Construction projects operate on razor-thin margins. A single measurement error or a miscommunication between the architect and the fabricator can lead to costly delays, wasted materials, and on-site chaos. This is where the technical precision of shop drawings becomes the backbone of a successful build.

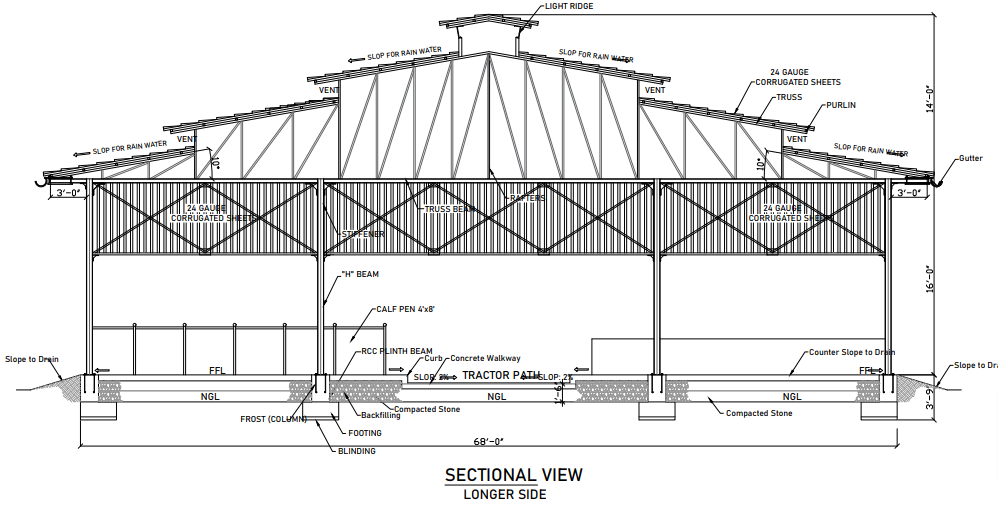

While architectural drawings provide the artistic vision and general layout of a structure, they often lack the granular detail required for actual fabrication and installation. Shop drawings bridge this gap. They are the detailed diagrams, schedules, and data sheets created by contractors, suppliers, and manufacturers to explain exactly how specific components will be built and installed.

Utilizing professional Structural shop drawings services changes the trajectory of a project. These drawings translate design intent into a language that fabricators and installers understand perfectly. For builders looking to maintain quality control and keep budgets in check, investing in high-quality shop drawings is not just an administrative step—it is a strategic necessity.

Enhanced Accuracy and Reduced Errors

The primary function of a shop drawing is to ensure that the component being built matches the reality of the construction site, not just the theory of the architectural plan. Architectural drawings are often conceptual. They show what the building should look like, but they don't always account for the physical clash of a steel beam with an HVAC duct or the precise bolt patterns required for a column connection.

Shop drawings scrutinize every millimeter of the design. During the drafting phase, drafters identify discrepancies in the original plans before any material is cut. This process, often aided by 3D modeling and Building Information Modeling (BIM), allows for "clash detection." Builders can see where structural elements might interfere with mechanical, electrical, or plumbing systems.

Correcting an issue on paper—or a computer screen—takes minutes and costs very little. Correcting that same issue on the job site requires cutting torches, new materials, and expensive crew downtime. By resolving these conflicts virtually, builders ensure that when materials arrive on site, they fit the first time.

Streamlined Communication and Collaboration

A construction site is a hub of diverse professionals: architects, structural engineers, general contractors, steel fabricators, and installers. Without a centralized, detailed source of truth, these groups often work in silos, leading to misinterpretations of the design.

Structural shop drawings serve as the universal language for the project. They provide a clear, agreed-upon set of instructions that every stakeholder can reference. When a fabricator looks at the shop drawings, they know exactly what specifications the engineer approved. When the installer is up on the scaffolding, they have a precise map of where every bolt and beam belongs.

This clarity significantly reduces the back-and-forth Request for Information (RFI) cycle that slows down many projects. instead of halting work to ask the architect for clarification on a connection detail, the answers are already detailed in the shop drawings. This streamlined communication fosters a more collaborative environment where teams spend less time arguing over vague plans and more time building.

Improved Project Timeline and Efficiency

Time is the most valuable currency in construction. Delays ripple outward, pushing back completion dates and inflating labor costs. Shop drawings are a critical tool for keeping a project on schedule, primarily through the power of prefabrication.

Because shop drawings provide exact dimensions and specifications, components like steel trusses, columns, and precast concrete panels can be manufactured off-site while the site preparation and foundation work are still underway. This parallel processing significantly compresses the project timeline.

Furthermore, firms that specialize in drafting, such as Archdraw Outsourcing, help accelerate the pre-construction phase. By handing off the complex task of drafting to dedicated experts, builders can focus on logistics and site management. Once the materials are delivered, the installation process becomes an assembly task rather than a fabrication task. There is no need for on-site welding or cutting to make things fit. The efficiency gained during installation can shave weeks off a commercial construction schedule.

Cost Savings and Waste Reduction

There is a misconception that high-quality shop drawings are an added expense. In reality, they are a cost-saving mechanism. The financial benefits manifest in two primary ways: material optimization and labor reduction.

First, shop drawings allow for incredibly accurate material take-offs. Fabricators know exactly how much steel, wood, or concrete is required, down to the last nut and bolt. This precision prevents over-ordering and reduces the amount of scrap material generated. In an era where material costs are volatile, buying only what you need protects the budget.

Second, the reduction in field labor is substantial. Field labor is generally more expensive and less efficient than shop labor. When crews have to modify components on-site because they don't fit, the cost per hour skyrockets. By ensuring components are perfect before they leave the factory, builders avoid unexpected labor overruns. The predictability provided by accurate drawings allows for tighter bidding and better profit margins.

The Foundation of a Successful Build

The complexity of modern construction demands more than just a good design; it demands flawless execution. Structural shop drawings provide the roadmap for that execution. They transform abstract concepts into tangible, buildable reality.

By prioritizing accuracy, fostering clear communication, accelerating timelines through prefabrication, and minimizing waste, these drawings offer a return on investment that far outweighs their initial cost. For builders who want to deliver projects on time and under budget, the path forward is clear: precise, professional shop drawings are not optional—they are essential.

Powered by Froala Editor

You may also like

More from this category.

Thông tin mới nhất về dữ liệu nhập khẩu Việt Nam và dữ liệu thương mại Việt Nam

How to Find Mobile Numbers on LinkedIn (Without a Sales Navigator Subscription)

Everything You Need to Know About Hyola Ultra 30k Prefilled Pods Box of 5

Real-World Longevity Test of Hyola Ultra 30k box of 5

Exploring and Understanding the Meaning of the Internet Slang Term TMB

How Quickly Should Bathroom Water Damage Be Addressed to Prevent Mold and Structural Issues in McLean VA Homes?

How Can Virtual Office Administrators Improve Operational Efficiency When You Hire Virtual Office Administrators for Scaling Businesses?

Powerful Real Estate Investment Strategies for Long-Term Success

Best Oil for Hair Growth in Pakistan: Benefits & Uses